Sustainable Synthetic Fibre-Reinforced Concrete

Manufacturers and suppliers of 100% recycled and virgin macro synthetic fibre

Enviromesh Synthetic Fibres

Enviromesh Synthetic Fibres have been embraced and widely used in pavements, precast, shotcrete and various other applications, as the end users recognise the benefits of replacing conventional steel mesh and steel fibres with synthetic fibre. Because Synthetic fibres are added to the concrete and mixed prior to pouring the concrete it saves both time and money by reducing the cost of transporting, handling, storage of conventional reinforcement.

Enviromesh has uniquely packaged the fibres in simple and easy to handle boxes of water-soluble pucks. The fibres are placed in the concrete mix. The pucks then dissolve within seconds, leaving the fibres to disperse evenly throughout the mix.

Learn more about Macro Synthetic Fibres

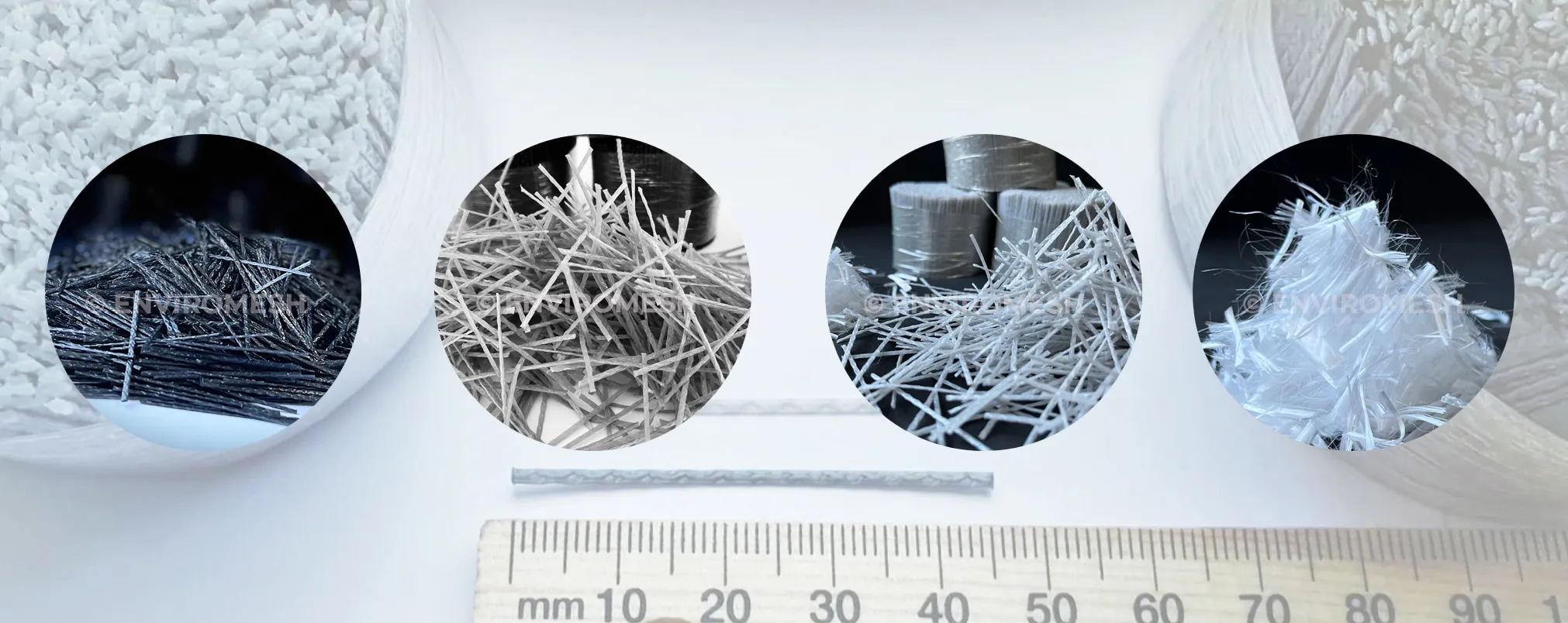

Macro Synthetic Fibres or MSF can be made from different kind of polymers. At Enviromesh we manufacture and supply MSF made from 100% recycled as well as virgin polypropylene. MSF help control shrinkage cracking, which can occur in the very early stages of concrete life. Macro synthetic fibres are larger than the micro synthetic fibres and are better dispersed when mixed in pre-pour concrete and increase the mechanical bond. Since MSF are non-corrosive, they are better than steel bar and steel mesh, specially in marine and coastal environments.

Learn more about Fibre Reinforced Concrete

Fibre Reinforced Concrete (FRC) is a material comprising cement, concrete or mortar mixed with fibres that are uniformly dispersed to achieve structural integrity. Both macro and micro synthetic fibres, steel fibres, natural and glass fibres of varying aspect ratios are used in FRC. The characteristics of the FRC are determined by the specific characteristics of the fibre used, quantity of the fibre used and type of concrete.

When fibres are added to mortar, the flexural strength of the composite is increased – depending on the proportion of fibres added and the mix design. Fibre technology actually transforms a brittle material into a more ductile one.

Catastrophic failure of concrete is virtually eliminated because the fibres continue supporting the load after cracking occurs. And while measured rates of improvement vary, fibre reinforced concrete exhibits higher post-crack flexural strength, better crack resistance, improved fatigue strength, higher resistance to spalling, and higher first-crack strength.

Advantages of Fibre Reinforced Concrete

Fibre reinforced concrete has more tensile strength compared to non-reinforced concrete. It reduces cracking and is an excellent alternate for projects where conventional reinforcement cannot be used. It improves the impact strength of concrete, reduces permeability which controls crack growth and makes the structure more durable.

Concrete reinforced with macro synthetic fibres is ideal for corrosive coastal and marine environments. Using FRC leads to substantial cost and time savings compared to using the conventional steel bar for reinforcement since fibre is pre-mixed with concrete and arrives on site ready to use.

Our Macro Synthetic Fibres

Specifications

- Conforms to ASTM C1116, Type III

- Minimum Tensile Strength is 650MPa

- Length is 47 mm

- Conforms to EN14889

Applications

- Precast

- Slab on ground

- Toppings

- Footpaths

- Shotcrete

100% Recycled

Macro Synthetic Fibre

Specifications

- Conforms to ASTM C1116, Type III

- Minimum Tensile Strength is 400MPa

- Length is 47 mm

- Conforms to EN14889

Applications

- Footpaths

- Shared User Path

- Pavements

- Open Channels

- Precast

Specifications

- Conforms to ASTM C1116, Type III

- Minimum Tensile Strength is 550MPa

- Length is 65 mm

- Conforms to EN14889

Applications

- Underground Support Shotcrete

- Stabilising Rock and Soil Slopes

- Bunds

- Repairs

- Open Channels

Specifications

- Conforms to ASTM C1116, Type III

- Minimum Tensile Strength is 500MPa

- Macro 47 mm / Micro 12 mm

- Conforms to EN14889

Applications

- Medium Impact Pavements

- Topping

- Precast

- Shotcrete

- Decorative Stencil Concrete

Benefits of Synthetic Fibres

Sustainable Alternative To Steel

Synthetic fibres have a lower environmental footprint due to lower carbon emissions during production and transportation, compared to steel fibre or steel mesh.

Cost-effective

Because Synthetic fibres are added to the concrete and mixed prior to pouring the concrete you will save both time and money by reducing the cost of transporting, handling, storage of conventional reinforcement.

Faster And Safer To Use

Synthetic fibres are easier to use without the need to cut steel mesh or manoeuvre mesh and bar chairs. They are easy to place and finish using a steel trowel, wood float or broom. It also reduces injury risks for workers.

Increased Asset Life

Synthetic fibres are non-corrosive and offer higher durability in acidic and alkaline environments. Through tighter crack control, they also prevent water seepage into concrete and extend the asset life.

We Are Proud Members Of

Our Customers

Our Supply Partners

Latest Media & News

Enviromesh eMesh fibres recently featured in Australian Department of Agriculture, Water and Environment’s series of videos published to promote use of recycled content in construction and infrastructure projects.

Video courtesy: Australian Department of Agriculture, Water and Environment