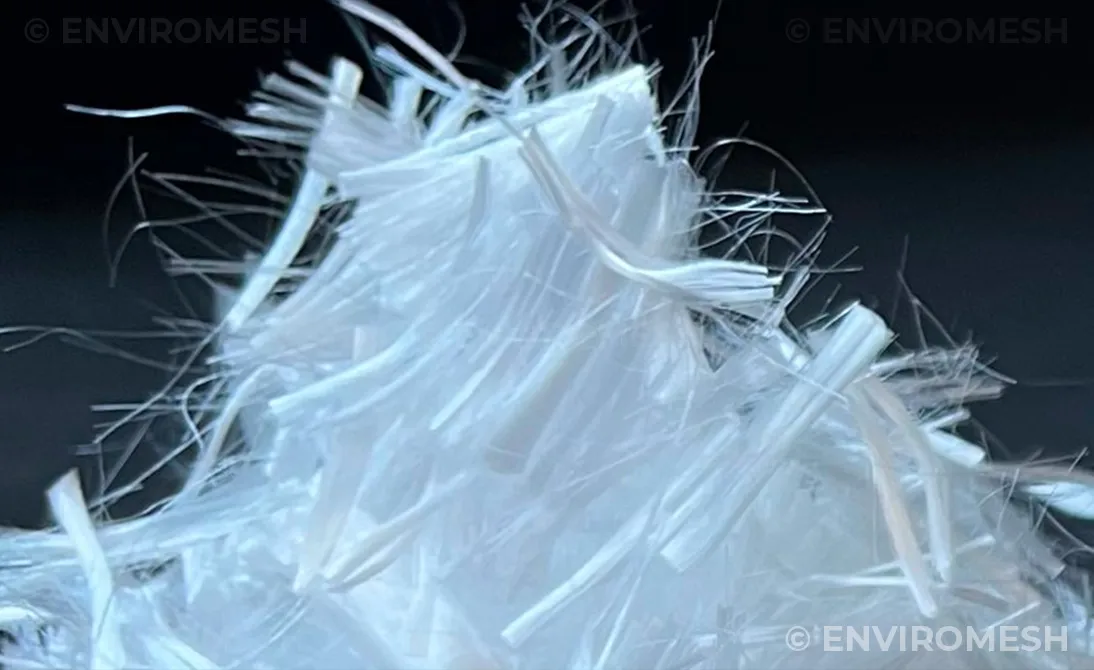

Macro Synthetic Fibres (MSF) for Concrete Reinforcement

Macro Synthetic Fibres or MSF can be made from different kind of polymers. At Enviromesh we manufacture and supply macro synthetic fibres made from 100% recycled as well as virgin polypropylene. Macro synthetic fibres help control shrinkage cracking, which can occur in the very early stages of concrete life. Macro synthetic fibres are larger than the micro synthetic fibres and are better dispersed when mixed in pre-pour concrete and increase the mechanical bond. Since macro synthetic fibres are non-corrosive, they are better than steel bar and steel mesh, specially in marine and coastal environments.

History & Development

Macro Synthetic Fibres have been around since the 1960s, with the first commercial use as MSFRC recorded in the 1990’s. Research into new fibres for concrete continues today as acceptance for macro synthetic fibres as a structural reinforcement grows globally. More recently, several leading institutions in Italy, Spain, Belgium and Switzerland have undertaken research in the use of macro synthetic fibres as concrete reinforcement.

The MSFA (Macro Synthetic Fibre Association) has traced the development of the macro synthetic fibres to 3M USA in the 1990’s followed by Japan. Australia has been very accepting of using the macro synthetic fibres in reinforced shotcrete for ground stabilisation in mines, with a near 100% uptake. Their latest market report from September 2021 reports a 10% per year growth in macro synthetic fibres uptake globally over the last five years. It also acknowledges macro synthetic fibres as a sustainable construction material in comparison to steel with significant reductions in carbon footprint. This has contributed to the growing use of macro synthetic fibres worldwide, especially as there is a greater need to reduce the carbon footprint in the construction industry.

Benefits of Macro Synthetic Fibres Reinforcement

Macro Synthetic Fibres as a concrete reinforcement have many benefits. They are more sustainable, economic, faster, safer and easier to use than conventional steel mesh and offer crack control in both plastic and hardened states.

Sustainable Alternative to Steel

Steel is expensive and is increasingly becoming difficult to source with global shortages. Compared to steel fibres or steel mesh, macro synthetic fibres have a lower environmental footprint across all seven main indicators. The potential savings for acidification, ozone depletion, eutrophication, photochemical oxidation, abiotic depletion (elements) and abiotic depletion (fossil fuels) are even higher.

Faster and Safer to use

The fibres are simpler and faster to use without the need to cut steel mesh or manoeuvre mesh and bar chairs. They are easy to place and finish using a steel trowel, wood float or broom. Since macro synthetic fibres reinforced concrete offers safer and quicker working environments, it translates to projects being completed with fewer staff available on site. Not only that but it also reduces the injury risks for workers including trip hazards caused by using traditional steel mesh, thereby ensuring further staff availability is not impacted. These are considerable benefits which enable timely completion of projects.

Cost-effective

Unlike steel bar or mesh, macro synthetic fibres reinforced concrete comes ready to place, pre-mixed in the concrete. It also means that inspection of the site is not required once the concrete has been placed at the project site. This reduces delays in project completion which means more cost savings. The fibres are pre-mixed in the concrete as an admixture reducing transportation, storage, and handling costs. The three-dimensional reinforcement throughout the concrete results in correct placement.

Synthetic Fibres Applications

Synthetic fibres can be used in a wide range of applications from secondary shrinkage reinforcement to primary reinforcing in underground shotcrete. They offer both micro and macro crack control. Typically, macro synthetic fibres are used in:

Shotcrete

Toppings

Open Channels

Precast

Pavements

Pathways

Slab on Ground

Shared User Paths

Roads

Footpaths

Stencil Concrete

Cycleways

Our Synthetic Fibres

Enviromesh macro synthetic fibres have been embraced and widely used in pavements, precast, shotcrete and various other applications, as the end users recognise the benefits of replacing reinforcing bar and mesh with synthetic fibre. Structural synthetic fibre is superior to more conventional reinforcement in shotcrete as it can outperform, give greater cost savings, is easier to use and safer to handle.

Enviromesh has uniquely packaged the fibres in simple and easy to handle boxes of water-soluble pucks. The fibres are placed in the concrete mix. The pucks then dissolve within seconds, leaving the fibres to disperse evenly throughout the matrix.

Enviromesh eMesh

eMesh is a 100% recycled macro synthetic fibre so in addition to the benefits of macro synthetic fibres reinforced concrete, eMesh promotes sustainability while delivering environmental and social benefits without adding cost to the construction and infrastructure projects.

Features

Provides good impact, fatigue, and shrinkage control in all types of concrete

Easy to use in all concrete

Its positive mechanical anchorage gives exceptional 3-dimensional post crack control

Mixes consistently and uniformly

Very economical

Description

- 100% Recycled

- 47mm Macro Synthetic fibres

Typical Applications

- Footpaths and Cycleways

- Pavements and Slab on Ground

- Shared User Paths

- Open Channels

- Precast Products

Enviromesh MP47

These fibres show very defined ductile behaviour characteristics. Performance levels are excellent in general shotcrete, pre-cast products and highly corrosive environments.

Features

Provides good impact, fatigue and shrinkage control in all types of concrete

Easy to use in general purpose applications as slab on ground, precast products, toppings

Excellent post crack control (toughness)

Its positive mechanical anchorage gives exceptional 3-dimensional post crack control

Performs well as a shrinkage crack control fibre

Finishes below surface with clean and clear edges

Mixes consistently and uniformly

Very economical

Description

- 100% Virgin Polypropylene

- 47 mm Macro Synthetic Fibres

Typical Applications

- Precast

- Toppings

- Slab on ground

- Footpaths

Enviromesh MPP

Enviromesh MPP has been designed to provide both plastic shrinkage control in early age concrete and micro crack control in hardened concrete. Combination of MP47 and micro fibres offer both micro and macro crack control.

Features

Provides good impact, fatigue and shrinkage control in all grade concretes

Easy to use in medium performance pavements

Is suited for hand and conventional finishing

Is exceptionally good in post crack control

Its positive mechanical anchorage gives exceptional 3-dimensional post crack control

Performs and sprays well in shotcrete applications

Very Economical

Description

- 47mm Macro Synthetic Fibres

- With Fibrillated Micro Fibres

Typical Applications

- Pavements Light Duty to Medium Impact, roads, paths, bikeways

- Toppings

- Precast

- Shotcrete

- Decorative Stencil concrete

Enviromesh MP

Micro synthetic fibres come in 300 gms bags. The fibres are used for the reduction of plastic shrinkage cracks, to improve impact, shatter and abrasion resistance, to increase fatigue resistance, to increase toughness and provide long term fire durability of concrete and cement-based building products.

Features

Enviromesh Micro synthetic fibres are an alternate system to welded wire fabric when used for non-structural concrete.

Micro synthetic fibres helps in prevention of early age drying shrinkage (plastic shrinkage)

Increases fire resistance protection in concrete by reducing explosive spalling

Saves construction time & money by eliminating purchase, storage, handling, cutting, placing and waste of welded wire fabric

Requires no minimum amount of concrete cover

Safe and easy to use

Will not rust or corrode; chemically inert

Non-magnetic - 100% Alkali proof - Provides long term durability

Description

- 100% Virgin Copolymer

- Fully Oriented, Micro Filament fibres

Typical Applications

- Pavements

- Footpaths

- Industrial Floors

- Loading Docks

- Precast Products

- Shotcrete Precast

Enviromesh SMP65

These fibres show very defined ductile behaviour characteristics. Performance levels are excellent in shotcrete, pre-cast products and highly corrosive environments.

Features

Provides good impact, fatigue and shrinkage control in all grade concrete

Easy to use in premium performance shotcrete

Excellent post crack control (toughness)

Its positive mechanical anchorage gives exceptional 3-dimensional post crack control

Performs and sprays well in shotcrete applications

Mixes consistently and uniformly

Very Economical

Description

- 65mm Macro Synthetic Fibres for Shotcrete

- Structural Macro Fibres

Typical Applications

- Shotcrete for underground support

- Bunds

- Repairs

- Open Channels

Fibercon Steel Fibres

Steel fibres strengthen concrete by resisting tensile cracking. Fibre reinforced concrete has a higher flexural strength than that of unreinforced concrete and concrete reinforced with welded wire fabric. But unlike conventional reinforcement – which strengthens in one or possibly two directions – steel fibres reinforce isotropically, greatly improving the concrete’s resistance to cracking, fragmentation, spalling and fatigue.

The specific effects on matrix mechanical properties greatly depend on the type and quantity of fibre used. Generally speaking, smaller fibres with a high fibre count offer superior first-crack strength and better fatigue endurance. Should a crack open widely, longer fibres with mechanical anchorage mechanisms offer better post-crack performance.

Steel fibre reinforced concrete is a castable or sprayable composite material of hydraulic cements, fine and/or coarse aggregates with discrete steel fibres of rectangular cross-section randomly dispersed throughout the matrix.

Steel fibre reinforced concrete acts as a uniform composite material. Compared to plain or conventionally reinforced concrete, the most immediate differences are improved ductility and post-crack performance.

Product List

- Fibercon 65/35

- Fibercon 65/60

- Fibercon 80/60

- Fibercon S38

- For more information on SFRC and its applications visit Fibercon

Description

- Fibercon has a range of steel fibres available in lengths from 38 mm to 50 mm and aspect ratios between 40 and 60. The fibres are manufactured either deformed or hook end and conform to ASTM A-820.