Enviromesh Fibre-Reinforced Concrete Solutions

Manufacturers and suppliers of 100% recycled and virgin macro synthetic fibre

Who We Are

Enviromesh prides in its commitment to the environment and sustainable construction.

We started as Fibercon in 1994 and have been involved in engineering, designing, and supplying fibres for both Macro Synthetic Fibres (MSFRC) and Steel Fibre Reinforced Concrete (SFRC) in the Asia Pacific region.

With our focus on sustainability and the future, in 2013 we partnered with James Cook University and undertook a full cycle research and development program to develop a unique recycled macro synthetic fibre. After successful trial in 2015, eMesh was introduced to the Australian infrastructure projects. In the same year, eMesh won the Australian Innovation Challenge Award in the manufacture & infrastructure category.

In 2020, when the business changed hands, Fibercon became Enviromesh.

eMesh is now widely used as a sustainable alternative of steel mesh and steel fibres in concrete construction in infrastructure projects across Australia.

Buoyed by the widespread acceptance and use of eMesh as a sustainable alternative in the construction and infrastructure industry, in 2021 we have partnered with RMIT University, where their leading researcher is developing low-carbon precast concrete using cardboard waste. Research will be conducted by RMIT University and funded through the Victorian government’s Research and Development Fund.

We strongly believe in inclusion and diversity. By the end of 2021 we have provided over 13,000 hours of work to NDIS supported workers at McCallum Industries in Ballarat, Victoria. We do not engage or support Modern Slavery in any form and are committed to ensuring that we comply with the legislation set out in the Australian Government Modern Slavery Act 2018.

We are a founding member of the Macro Synthetic Fibre Association (MSFA) as well as members of the Infrastructure Sustainability Council (ISC) and Institute of Public Works Engineering Australasia (IPWEA). We source all the raw materials, products, and packaging from reputable suppliers who support the same values regarding ethical sourcing and social responsibility.

We focus continually upon why we exist, which is to help the environment through ethical growth. So, everything that we do is a solution and service for our customers, helping customers meet their environmental objectives, help the environment in the true spirit of a win/win.

To achieve this, we simply understand what business we are in.

Enviromesh is fortunate to have the best fibre team and a network of businesses we work with in Australia and NZ, who do exactly that.

What We Do

Enviromesh aims to make the construction process simple with high value outcomes through our concrete reinforcement solutions. One of the ways we do this is by offering both standard and custom fibre types and sizes along with custom packaging.

Given our experience within the industry, especially with Local Council Projects, we are uniquely placed to provide fibre systems, support, and engineering design solutions for infrastructure projects of any size and scale.

Fibres are used for various infrastructure applications. So, while fibres may not be used in the motorway or bridge, they are used in many of the ancillary applications such as footpaths, embankments, ramps and shotcretes.

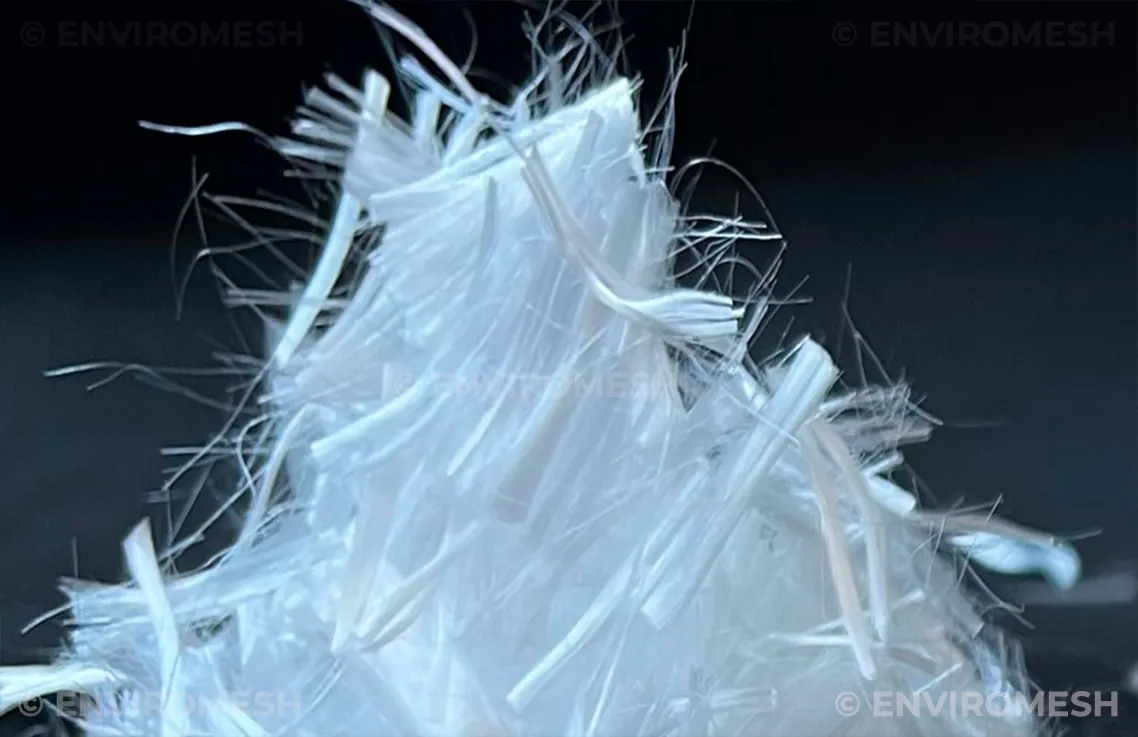

Our Macro Synthetic fibres – eMesh, MP47, MPP and SMP65 – are engineered and graded length synthetic fibres which have been specifically developed to provide a higher level of secondary concrete reinforcement. By combining the benefits and performance characteristics of polypropylene fibres, our Macro Synthetic products provide a non-corrosive alternative to steel fibre and mesh reinforcement.

Our Macro Synthetic fibres are designed to offer resistance to cracking as well as improved toughness and energy absorption. Additional benefits include increased impact and shatter resistance as well as enhanced shear strength and fatigue endurance.

eMesh is 100% recycled plastic macro synthetic fibres which completely replace virgin plastic fibres or steel reinforcing mesh.

eMesh offers up to 90% reduction in CO2 and water required in production as compared to steel mesh. We source the raw material locally and the fibres are manufactured in Australia and packaged by NDIS supported workers.

eMesh controls the risk of shrinkage and cracking during both the early and later stages of concrete life. It offers the same level of reinforcement in concrete as non-recycled fibres, but it’s more cost-effective and environmentally friendly.

Our – Micro Synthetic Fibres – MP – is a range of widely used synthetic fibres which are designed to offer early age benefits such as resistance to plastic shrinkage and settlement cracking. Additional benefits include reduced bleeding, impact and shatter resistance, and improved durability and resistance to explosive spalling.

We have a third-party audited Environmental Product Declaration for MP47, eMesh, SMP65 and MPP. All our synthetic fibres are classified within group 355 (man-made fibres) under the UN CPC classification system.

Fibercon Steel Fibres – S38, 65/35 and 65/60 – are a high-quality range of cold-drawn steel wire fibres designed to offer resistance to long term cracking as well as increasing the toughness and energy absorption qualities of concrete.

Where We Make A Difference

Councils & Large Infrastructure

The use of eMesh, a 100% recycled synthetic fibres, allows local councils to specify and purchase sustainable and environmentally beneficial solutions for their footpaths, cycleways and shared user paths. Our fibres are packaged by NDIS supported workers which allows councils and infrastructure developers to keep their commitments to deliver the right social outcomes through their social procurement framework.

Maritime & Coastal Infrastructure

Our synthetic fibres offer improved long‐term serviceability of maritime and coastal infrastructure as concrete is susceptible to degradation through corrosion, alkali‐silica reaction, sulphate attack, and ingress of aggressive solutions such as sea water. Our synthetic fibres are non-corrosive, alkali resistant and in place of conventional steel reinforcement can improve durability of the concrete, prolonging the life of the assets.

Concrete Precast

Using Enviromesh synthetic fibres gives precasters the freedom to produce modern unconventional shapes easily and quickly without the need for cutting and welding mesh and bar. Eliminating the need for steel cage positioning, set up and fixing greatly improves mould utilisation times and reduces production costs along with reduced labour, reduced breakage, and an overall savings in reinforcement costs.

Mining Applications

Through our Australian manufacturing operation, we have the ability to tailor our synthetic fibres specifically for the shotcrete used in your mine. By reviewing and refining the techniques used in the production and application of sprayed concrete, we can assist you in tailoring the concrete mix designs, fibre types and dose rates to the local materials and conditions, optimising the finished shotcrete product at the most economical cost possible.

Industrial & Warehousing

Synthetic fibres can improve the life cycle of your factory or warehouse slab and deliver savings due to reduction in labour, construction time and setup time. Improved ductility means increased energy absorption, fatigue life, and impact and abrasion resistance. Durability improves as the width and number of cracks are minimised, reducing the penetration of potentially harmful chemicals into concrete and further reducing the long-term costs associated with damage, repair and maintenance of your slab.

Looking for a supplier in your region?

Provide us your contact details and one of our team members will get in touch shortly.

Our Team

ALEX LESTER

MANAGING DIRECTOR

Alex is responsible for supporting and communicating, our many successes on behalf of the best fibre team in Australia externally, and leading the development and effective implementation of the company’s short and long-term growth strategies. After a long career in senior management roles in fibres, mining, dairy and business consulting, Alex is relishing the new challenge of being the MD at Enviromesh.

STUART NEILSON

STRATEGY & SALES

Stuart is responsible for strategy and development of all the sales for Enviromesh, making sure our partners have the best possible solution for their project.

Stuart has 30 years fibre experience internationally and in Australasia. He is passionate about fibre being a better solution for producing sustainable concrete and enriching our circular economy.

JANE WALBANK

CLIENT SERVICES

Jane has over 20 years’ experience in administration and customer service. Her eye for detail compliments her enthusiasm, professionalism, and efficiency with which she helps our customers.

Jane manages day-to-day enquiries and is the first point of contact for assistance with ordering and invoicing.

MONICA SINGH

INFORMATION & COMMUNICATIONS

Monica has over 15 years of experience in project and stakeholder management. She has worked in professional and vocational education, as well as in civil infrastructure industry.

At Enviromesh, Monica is responsible for overseeing and coordinating internal and external communications.

MAAN SHEKHAWAT

GROWTH, DIGITAL & IT

Maan helps Enviromesh catalyse its growth by building new relationships and partnerships. He is also responsible for all things Digital and IT.

He is passionate about innovations and emerging technologies that help organisations reduce their carbon footprint and work towards Net Zero targets.

We Are Proud Members Of

Our Customers

Our Supply Partners

Latest Media & News

Enviromesh eMesh fibres recently featured in Australian Department of Agriculture, Water and Environment’s series of videos published to promote use of recycled content in construction and infrastructure projects.

Video courtesy: Australian Department of Agriculture, Water and Environment